Front panels

in all shapes, colours and materials

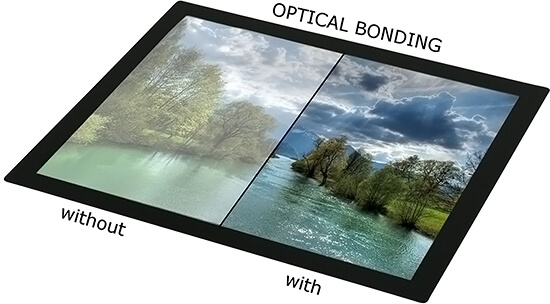

Optical Bonding

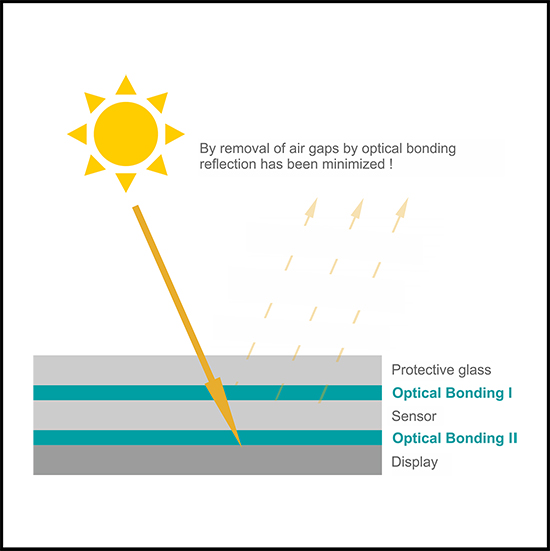

Here are sticked together both touch screens and glass plates with each other ("Optical bonding 1") or with the display ("Optical bonding 2") under clean-room conditions.

The advantages

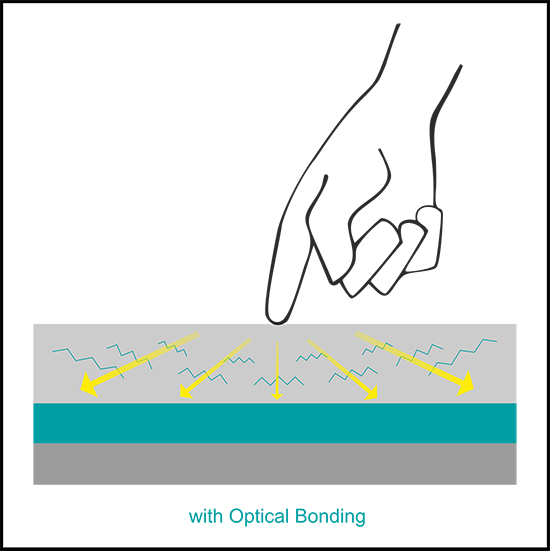

- less reflection

- longer service life

- higher robustness

- no condensation

- dust-free execution

- improved appearance

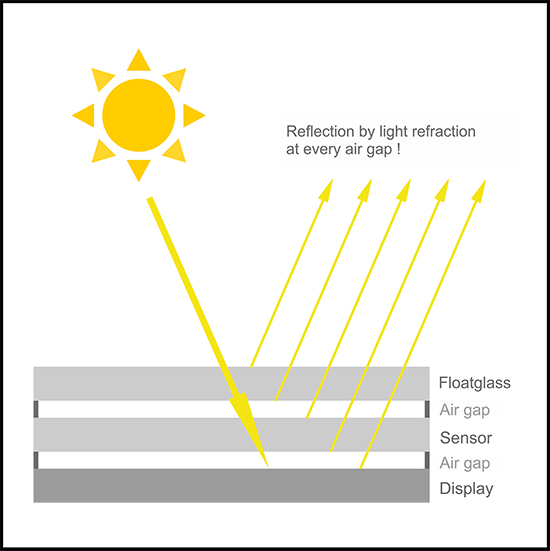

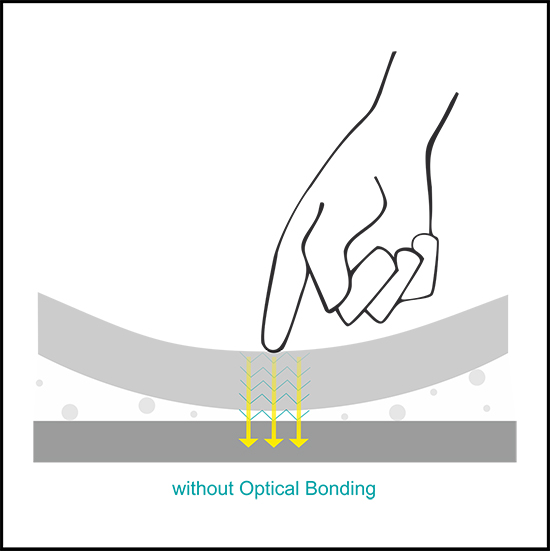

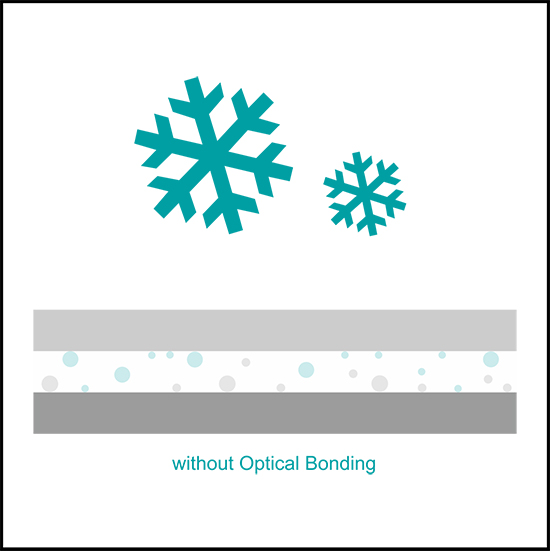

without Optical Bonding

with Optical Bonding

- less reflection - by sticking together the glass plates light refraction is reduced and the contrast increased. Therefore better readability without higher power consumption even in case of critical lighting conditions

- improved appearance - improved appearance of the display to the user

- dust-free execution - by cleanroom production is the inclusion prevents particles and consequent visual impact

- no condensation - as there is no air gap between glass plate and touch screen or display, no moisture can penetrate and settle out, condensation is excluded.

- higher robustness - a bonded design is more stable and resistant against mechanical loads, thus the device becomes generally more robust, too.

- longer service life - by closing the isolating air gap between the glass plates heat can escape to the outside, a better heat dissipation is created.

We offer our Optical Bonding Service - independently or complementary for every available display. The standard use Wet-Bonding material based on a acrylat system and has the following advantages:

- curing also in covered areas (e.g. printing) possible

- high adhesive power

- avoid delamination effects

- silicone-fee for sensible parts

Addionally we have also experience in qualification and procurement of displays.

Request us!

WÖHR sectors in one click